Introduce the topic broadly while integrating the main keyword naturally in the opening paragraphs. Explain the meaning of robotic construction technology in the construction industry and the importance it is gaining in recent years.

What is Robotic Construction Technology?

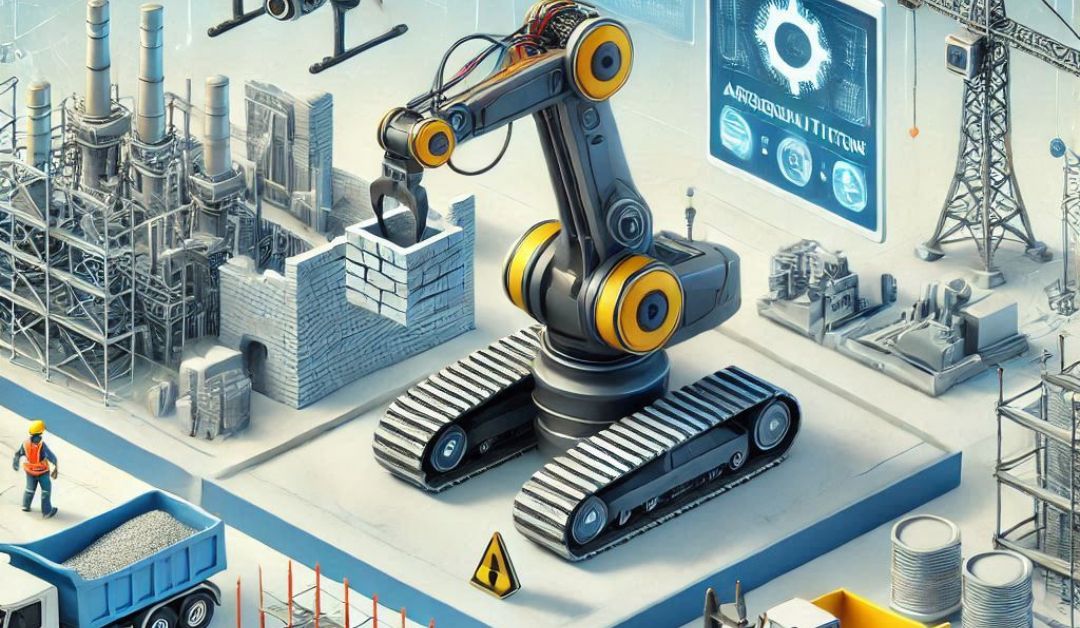

Robotic construction technology refers to the application of advanced robotics and automation systems in the construction industry. These technologies utilize robotics to perform tasks such as bricklaying, 3D printing, site monitoring, and even structural assembly. Gone are the days when physical labor was the only driving force on construction sites. Robotic construction technology is now empowering builders with precise, efficient, and innovative tools.

This approach bridges the gap between manual construction practices and modern automation. With the increasing demand for smart infrastructure and sustainable building methods, robotics has become essential for staying competitive. From simplifying repetitive tasks to tackling high-risk operations, robotic construction technology aims to revolutionize how projects are executed.

Why is Robotic Construction Technology Important in Modern Construction?

The construction sector has long struggled with inefficiency, skill shortages, and safety concerns. Robotic construction technology provides solutions to all these challenges. Its importance lies in improving cost-effectiveness, minimizing errors, and accelerating project timelines. For example, advanced robots used for 3D printing can construct entire walls or even buildings in record time.

Additionally, integrating automation into construction introduces consistency and precision. Unlike human workers, robots don’t tire, allowing them to perform complex tasks with unparalleled accuracy. Most importantly, they enhance safety by undertaking risky assignments such as handling heavy loads or working in hazardous environments.

The Evolution of Robotics in the Construction Industry

The evolution of robotic construction technology has been extraordinary. It began with basic mechanized tools and has now advanced to a stage where autonomous drones and robotic arms are commonplace. Companies worldwide are adopting these technologies at a rapid pace. For instance, robotic bricklayers can lay up to 1,000 bricks per hour, while drones are being used to survey vast construction sites efficiently.

Over the years, innovation in artificial intelligence (AI) and machine learning has further enhanced the functionality of construction robots. These systems are not only faster but smarter, whether it’s about navigating uneven terrain or customizing designs in real-time. The shift from manual labor to automation marks a new era of productivity in construction.

Key Applications of Robotic Construction Technology

Autonomous Bricklaying and Wall Construction

One of the most practical uses of robotic construction technology lies in bricklaying and wall construction. Machines like robotic arms can lay bricks faster and with greater consistency than human workers. These robots are equipped with sensors and AI to ensure every brick is perfectly aligned.

For example, the Semi-Automated Mason (SAM) is a robotic system designed to assist with large-scale wall construction. It not only increases productivity but also allows human masons to focus on more intricate parts of the project.

3D Printing and Robotic Manufacturing in Construction

The combination of robotics and 3D printing is rapidly transforming construction. Robotic 3D printers can create entire building components, and in some cases, entire houses, using sustainable materials such as concrete and recycled plastics. These 3D printing robots reduce material waste and offer unprecedented design flexibility.

For instance, robotic construction technology has enabled the building of houses in remote areas where traditional construction would be too costly or logistically challenging. These systems are already being tested to construct futuristic smart cities.

Site Monitoring and Surveillance with Drones

Construction site management can be complex, especially on large-scale projects. Drones powered by robotic construction technology help streamline site monitoring and surveillance. These autonomous aerial machines can provide high-resolution imagery and scans to assess progress or identify potential issues in real time.

From analyzing terrains to pinpointing unsafe areas, drones help teams stay updated about their projects’ status without physically entering hazardous zones. This not only saves time but also ensures safety.

Heavy Lifting and Excavation Using Robotic Equipment

Heavy-duty robots designed for lifting and excavation have become essential on modern construction sites. These machines are particularly beneficial for tasks that require immense strength, such as moving steel beams or excavating challenging terrains.

Excavation robots, for example, are used for tunnel construction projects where operating conditions are too dangerous for human workers. By incorporating automation in these tasks, construction companies can reduce costs associated with manual labor while improving speed and efficiency.

Benefits of Robotic Construction Technology

Enhanced Efficiency and Reduced Labor Costs

One of the biggest advantages of robotic construction technology is its ability to complete tasks efficiently without additional manpower. For example, a single robot performing repetitive tasks like bricklaying or welding can replace a large crew, significantly reducing operational costs.

Robotic automation ensures projects are completed faster without losing quality, making it easier to deliver under tight deadlines. It allows companies to optimize labor resources effectively, channeling skilled workers into more creative or supervisory roles.

Improved Safety Standards in Hazardous Environments

Robots can operate in high-risk zones such as demolition sites or unstable structures, reducing the need for human involvement in dangerous tasks. For instance, drones can inspect skyscrapers or tunnels, while ground robots handle explosive materials. The result is fewer construction-related injuries and deaths.

Greater Precision and Design Capabilities

Construction errors can be costly and time-consuming. Robotic systems eliminate inaccuracies, ensuring uniform quality across projects. For example, 3D printing robots create structures layer by layer with flawless precision, allowing for intricate designs that would otherwise be impossible using traditional methods.

Sustainable and Eco-Friendly Construction Practices

Robotic construction technology helps reduce environmental impact by using materials more efficiently and cutting down on waste. Systems like robotic 3D printers also enable the use of sustainable materials, promoting eco-friendly construction practices.

Challenges Facing Robotic Construction Technology

High Initial Costs of Robotic Implementation

Adapting robotic construction technology requires substantial upfront investment, which can deter smaller construction companies. The high costs of equipment, software, and training often slow down widespread adoption in the industry.

Technical Expertise and Workforce Training Requirements

Operating advanced construction robots requires a skilled workforce. This means that companies must invest in training or hire specialized professionals, which can be both time-consuming and expensive.

Integration of AI and Robotics with Traditional Tools

Another challenge lies in integrating robotic systems with existing construction processes. Compatibility between traditional and modern tools can be challenging, requiring customizations or entirely new workflows.

Ethical and Employment Concerns in the Construction Sector

The rise of robotic construction has raised ethical questions about job displacement. While robots increase efficiency, they reduce dependency on manual labor, potentially impacting employment opportunities in construction.

Future of Robotic Construction Technology

The Role of Artificial Intelligence in Advancing Robotics

AI will continue to play a key role in future developments, enabling robots to operate independently, learn from data, and make real-time decisions. For example, AI-driven robotic arms could assemble complex structures without human intervention.

Sustainable Design and Green Building with Robots

The focus on eco-friendly practices will inspire advancements in robotics that prioritize sustainability. Future construction robots are likely to use renewable energy sources and work in tandem with environmental conservation goals.

Integration of IoT for Smarter Construction Robots

The Internet of Things (IoT) will further integrate devices on construction sites, allowing robots to communicate and collaborate seamlessly. IoT-powered robotic construction technology will also improve monitoring and predictive maintenance.

What the Future Holds for Fully Autonomous Construction

The future may see construction projects managed entirely by autonomous robots. From site preparation to project completion, robotic systems promise to deliver faster and higher-quality builds.

Real-Life Examples and Case Studies

Case Study: Robotic Bricklayer Building X in Record Time

Robotic bricklayers like SAM have showcased how automation can improve both speed and cost-efficiency in wall construction projects across cities.

How 3D Printing Robots are Changing Architectural Design

Companies such as ICON and Apis Cor are pioneers in using robotic 3D printing technology to build homes in challenging environments.

Pioneering Companies in Robotic Construction Technology

Major players, such as Caterpillar and Boston Dynamics, continue to invest in robotic construction technology, shaping the growth trajectory of the industry.

Closing Thoughts on Robotic Construction Technology

Robotic construction technology is transforming the way we build, offering a blend of efficiency, safety, and innovation. While challenges like costs and employment concerns persist, the benefits far outweigh these hurdles. As we move toward smarter, more sustainable building practices, robotics will continue to pave the way for the future of construction.

Whether through autonomous 3D printing or AI-powered site surveillance, the applications of robotic construction technology are reshaping the industry. It’s not just about building structures—it’s about building better futures.

FAQs About Robotic Construction Technology

1. How does robotic construction technology enhance safety on construction sites?

Robotic construction technology improves safety by taking over hazardous tasks, such as demolishing unstable structures, working in confined spaces, or handling explosive materials. Drones and autonomous machinery can also monitor work sites and detect risks in real-time, reducing the chance of accidents.

2. What are the main benefits of using robotics in construction projects?

Key benefits include increased efficiency, reduced labor costs, enhanced accuracy, faster project completion, and improved sustainability. Robots can perform repetitive tasks with consistent precision and help minimize material waste, aligning

3. What are the challenges associated with adopting robotic construction technology?

Some challenges include the high initial cost of equipment, the need for specialized training to operate advanced machinery, and integrating robotics with traditional tools. Additionally, there are ethical concerns about potential job displacement in the industry.

4. Can robotic construction technology be used in small-scale projects?

Yes, robotic construction technology is increasingly adaptable for small-scale projects. For example, robotic 3D printers can create custom components for homes, and drones can efficiently inspect and monitor smaller construction sites. These innovations are becoming more accessible to contractors of all sizes.

5. What role does artificial intelligence (AI) play in robotic construction technology?

AI powers construction robots with capabilities like real-time decision-making, terrain analysis, and workflow optimization. It enables autonomous machines to adapt to changing conditions, perform specific functions, and even collaborate with other robots seamlessly on construction sites.