The world of robotics and automation is rapidly evolving, and with it comes an increasing need for sophisticated control systems. These systems are at the core of any robotic process, guiding and optimizing the operations that define modern manufacturing, healthcare, logistics, and more. This article will explore the importance of control systems in robotics and automation, how they work, and their applications across various industries. We’ll also delve into how control systems help improve efficiency and precision in automated processes.

What Are Control Systems in Robotics and Automation?

Control systems in robotics and automation refer to the mechanisms used to manage and control the behaviour of robots and automated machinery. These systems ensure that machines perform tasks efficiently, precisely, and safely. They consist of hardware and software components that process information and provide robot or automation system commands.

A control system can be either open-loop or closed-loop. In an open-loop system, the control input is provided without feedback, meaning that the system operates based on predetermined commands. On the other hand, a closed-loop control system uses feedback to continuously monitor and adjust the machine’s operation, ensuring that the desired outcome is achieved.

Integrating robotics and automation with control systems has revolutionized industries by enhancing precision, reliability, and productivity.

The Essential Role of Robotics and Automation in Modern Industries

In today’s fast-paced world, robotics and automation drive innovation across industries. The rise of smart factories, autonomous vehicles, and robotic surgeries showcases these technologies’ pivotal role in improving operational efficiency and safety. Control systems ensure that these automated systems perform their tasks seamlessly.

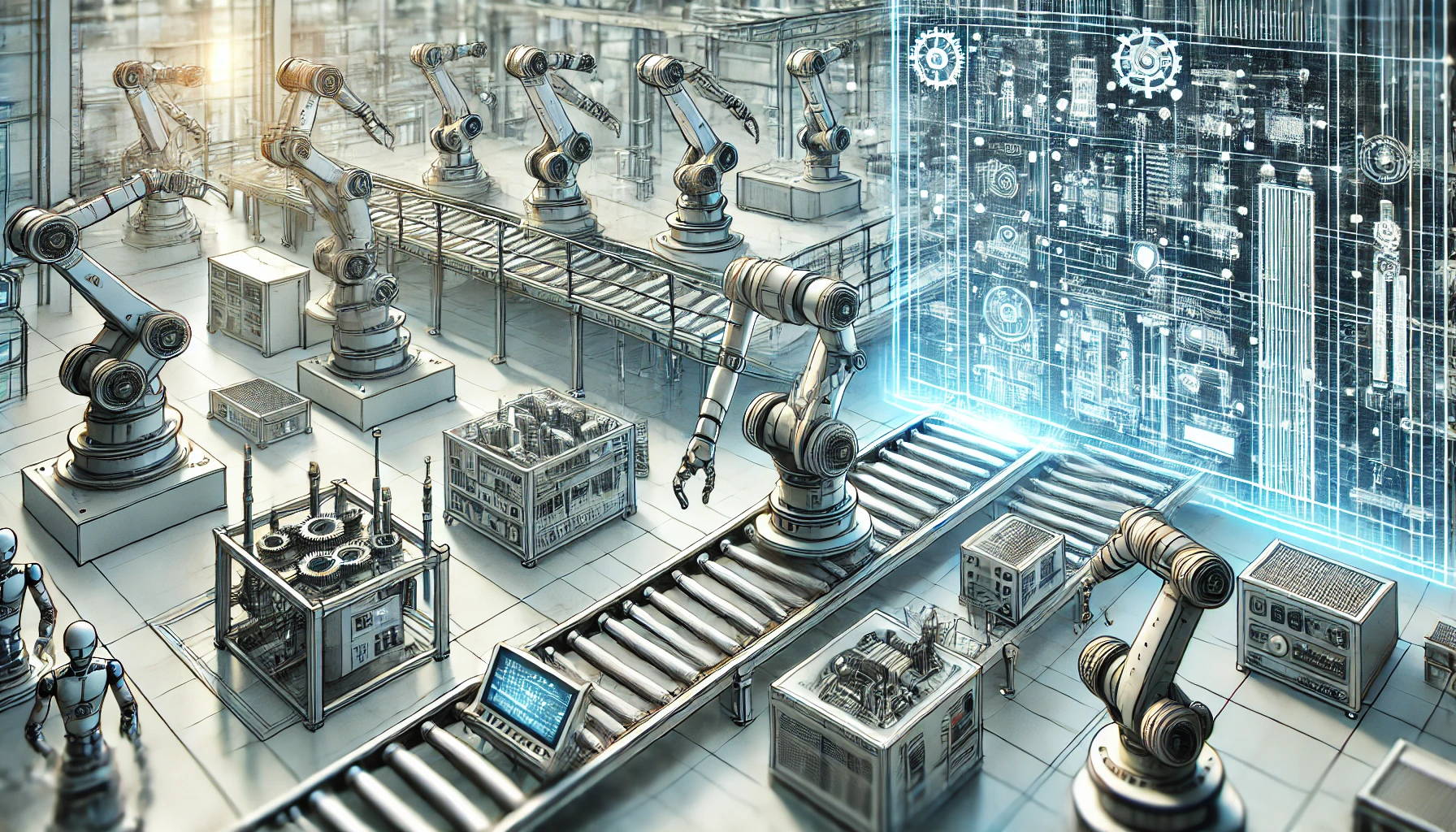

Robotics and Automation in Manufacturing

Manufacturing has been one of the primary beneficiaries of robotics and automation. Robots are deployed for various tasks, such as assembly, packaging, and material handling. Robots can work with high precision and speed through control systems, minimizing errors and maximizing throughput. Automated systems can also work 24/7, ensuring that production processes continue without interruptions.

Advantages of Control Systems in Manufacturing Automation:

- Increased Productivity: Automated systems driven by control systems can operate continuously, resulting in higher output and reduced downtime.

- Enhanced Precision: Robots can perform tasks with a level of accuracy that is difficult to achieve with manual labor, reducing defects.

- Cost Efficiency: Automation lowers labor costs and reduces the likelihood of costly errors.

Robotics and Automation in Healthcare

Robotics and automation are also making waves in healthcare. Robotic-assisted surgeries, rehabilitation robots, and automated diagnostic systems transform patient care. Control systems ensure these robots operate with the precision and responsiveness required in medical environments.

Advantages of Robotics and Automation in Healthcare:

- Improved Surgical Precision: Robots can perform surgeries more accurately, reducing human error and improving recovery times.

- Enhanced Patient Care: Automation allows for more efficient patient data management and tasks, enabling healthcare providers to focus more on patient care.

Robotics and Automation in Logistics

In logistics and supply chain management, robotics and automation are used for sorting, packaging, and transporting goods. Autonomous vehicles and drones are becoming increasingly common for delivering packages, and robots are used for warehouse management.

Key Benefits in Logistics:

- Faster Delivery: Automated delivery systems powered by control systems reduce delivery times.

- Reduced Operational Costs: Automation minimizes the need for human labour in repetitive tasks, significantly cutting operational costs.

How Control Systems Function in Robotics and Automation?

Control systems are the backbone of robotics and automation, providing the necessary intelligence to guide robots and machines through their tasks. Let’s explore the fundamental components that make these systems work.

Sensors and Actuators

Sensors are responsible for gathering data from the environment. In robotics, these sensors can detect temperature, pressure, motion, and more changes. Conversely, actuators carry out the control commands by converting electrical signals into physical motion, such as moving robotic arms or controlling a drone’s flight path.

Controllers and Software

At the heart of any control system is the controller, which processes the data received from sensors and makes decisions based on that information. Software programs embedded in the controller define the behaviour of the system, whether it’s adjusting the speed of a motor or performing a series of complex movements.

Feedback Mechanisms

Feedback plays a crucial role in closed-loop control systems. The control system constantly monitors the robot’s actions and adjusts the control input to achieve the desired outcome. This dynamic interaction ensures that robots and automated systems can adapt to environmental changes, such as unexpected obstacles or shifts in the required task.

How Control Systems Function in Robotics and AutomationVarious types of control systems are used in robotics and automation, depending on the complexity and requirements of the task at hand.

Proportional-Integral-Derivative (PID) Controllers

PID controllers are the most widely used type of control system. They help regulate robobehaviourems’ behaviour by considering the system’s present, past, and anticipated futbehaviourvior. PID controllers enable robots to maintain stable and accurate performance by adjusting parameters such as speed or position.

Model Predictive Control (MPC)

MPC is an advanced control method used in more complex robotic systems. It predicts the system’s future behavior using a model and makes adjustments accordingly. This method is ideal for applications where robots must anticipate changes and adjust their actions proactively.

Adaptive Control

Adaptive control systems can adjust to variations in the system or its environment. These systems are especially useful when environmental conditions are unpredictable, such as manufacturing processes involving different raw materials.

Challenges in Robotics and Automation Control Systems

While control systems have enabled remarkable advancements in robotics and automation, several challenges can be overcome.

Complexity in Programming

As robots become more sophisticated, programming and fine-tuning control systems can become increasingly complex. The need for high-level programming skills and integrating artificial intelligence and machine learning technologies adds another layer of complexity.

Safety and Reliability

Ensuring the safety and reliability of robotic systems is a significant concern. Control systems must be able to detect faults and respond to them quickly to prevent accidents and downtime. This is especially important in industries such as healthcare and autonomous vehicles.

Integration with Existing Systems

Integrating control systems with legacy systems and ensuring they work seamlessly together can be challenging. Compatibility issues, data transfer protocols, and hardware limitations must be addressed for smooth integration.

Prospective Trends in Robotics and Automation

As technology continues to evolve, the future of robotics and automation holds exciting possibilities.

AI-Powered Robotics

Artificial intelligence is increasingly being integrated into robotic systems, allowing robots to learn from their environment and adapt to changes. This could result in more autonomous and efficient robots handling more complex tasks.

Collaborative Robots (Cobots)

Cobots are designed to work alongside humans rather than replacing them. They are equipped with advanced sensors and control systems that enable them to work safely in human environments.

5G and IoT Integration

Integrating 5G networks and the Internet of Things (IoT) will enhance communication between robots, control systems, and other devices. This will lead to faster, more efficient automation processes and greater system interoperability.

FAQs

1. What is the importance of control systems in robotics and automation?

Control systems are crucial in robotics and automation because they regulate and guide robots to perform tasks efficiently, ensuring accuracy, safety, and reliability in automated processes.

2. How do control systems improve manufacturing efficiency?

Control systems enhance manufacturing efficiency by allowing robots to perform tasks autonomously, minimizing human error, and optimizing the use of resources, which results in higher productivity and reduced operational costs.

3. Can robotics and automation replace human workers?

While robotics and automation can perform repetitive and dangerous tasks, they are more likely to complement human workers by handling mundane tasks, allowing humans to focus on more complex and strategic roles.

4. What are some examples of industries using robotics and automation?

Industries such as manufacturing, healthcare, logistics, and agriculture use robotics and automation to improve operational efficiency, safety, and precision.

5. How do control systems in robotics handle real-time changes in the environment?

Control systems handle real-time changes using sensors and feedback mechanisms, which allow robots to detect changes in their surroundings and adjust their actions accordingly to maintain performance and safety.

Conclusion

Control systems are the driving force behind robotics and automation’s success, enabling machines to perform tasks autonomously and with high precision. As robotics and automation transform industries, control systems will evolve to meet new challenges and opportunities. Understanding how control systems work and their applications can help businesses stay ahead of the curve and leverage the full potential of these cutting-edge technologies.

With advancements in AI, 5G, and IoT, the future of robotics and automation looks promising, offering exciting prospects for industries worldwide. By integrating efficient control systems, businesses can continue to enhance productivity, improve safety, and streamline their operations.