In today’s fast-paced industrial landscape, businesses are continuously seeking ways to enhance efficiency, reduce costs, and improve product quality. One game-changing innovation making waves across industries is Industrial Automation. By integrating advanced technologies into manufacturing and operational processes, companies are unlocking unprecedented levels of productivity and competitiveness. In this article, we’ll explore the ins and outs of industry automation, its benefits, and how it’s shaping the future of modern businesses.

What is Industrial Automation?

Understanding the Basics of Industrial Automation

This involves the use of control systems, such as computers and robotics, to handle industrial processes with minimal human intervention. These systems are designed to operate machinery, monitor production lines, and ensure optimal performance. From automotive manufacturing to pharmaceuticals, This is transforming traditional workflows by replacing manual tasks with automated processes.

Key Benefits of Industrial Automation for Modern Industries

The adoption of automation offers a host of benefits:

- Increased Productivity: Automated systems work around the clock without fatigue, ensuring consistent output.

- Cost Reduction: By minimizing human errors and improving efficiency, businesses can significantly cut operational costs.

- Enhanced Quality: Automation ensures precision, resulting in superior product quality and uniformity.

- Improved Safety: Dangerous or repetitive tasks can be delegated to machines, reducing workplace accidents.

- Scalability: Automation enables businesses to scale operations swiftly to meet market demands.

How Industrial Automation Transforms Manufacturing Processes

In manufacturing, industrial automation revolutionizes processes by:

- Streamlining Workflows: Automated systems enhance coordination between different stages of production.

- Reducing Waste: Advanced sensors and data analytics optimize resource usage, minimizing material wastage.

- Accelerating Time-to-Market: Faster production cycles enable companies to bring products to market quicker than ever before.

Industrial Automation Solutions for Modern Businesses

Top Solutions for industry automation in 2024

As technology evolves, new automation solutions are emerging to cater to diverse industrial needs. Some of the top solutions include:

- Robotic Process Automation (RPA): Ideal for repetitive tasks like assembly and packaging.

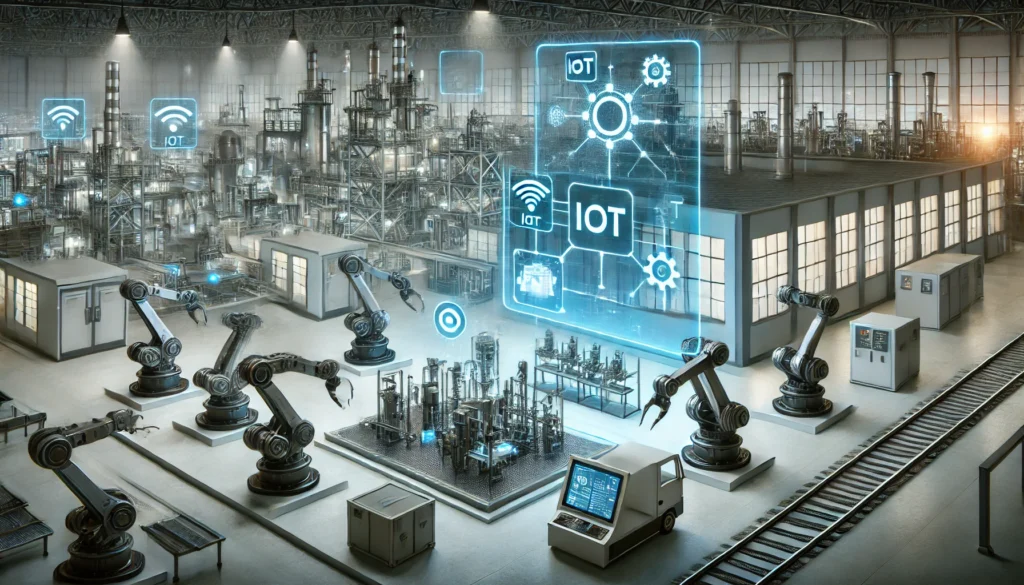

- Internet of Things (IoT): Connecting devices for real-time monitoring and predictive maintenance.

- Artificial Intelligence (AI): Enhancing decision-making and process optimization.

- Programmable Logic Controllers (PLCs): Central to controlling and automating industrial machinery.

Choosing the Right Industrial Automation Company

Partnering with the right industry automation provider is crucial for successful implementation. To make an informed decision:

Factors to Consider in industry automation Solutions

- Industry Expertise: Ensure the company has experience in your specific industry.

- Customizability: Look for solutions tailored to your unique operational needs.

- Technical Support: Reliable after-sales support is essential for seamless operation.

- Cost-Effectiveness: Evaluate the cost-benefit ratio of proposed solutions.

- Innovation: Choose a company that stays ahead with cutting-edge technologies.

Exploring Industrial Automation and Control Systems

Importance of Industrial Control Systems Security

With the growing reliance on automation, safeguarding industrial control systems (ICS) from cyber threats has become paramount. Robust security measures, such as firewalls, encryption, and intrusion detection systems, are essential to protect sensitive data and maintain uninterrupted operations.

Integrating Industrial Automation with Control Systems

Combining industry automation with advanced control systems enables real-time monitoring and management of processes. This integration leads to:

- Enhanced Efficiency: Automated systems work cohesively with control systems to optimize workflows.

- Proactive Maintenance: Predictive analytics detect potential issues before they cause disruptions.

- Data-Driven Insights: Control systems provide actionable insights to improve decision-making.

How to Optimize Industrial Automation and Control Systems

To get the most out of your automation and control systems:

- Invest in Employee Training: Ensure your workforce is skilled in operating and maintaining automated systems.

- Regular Upgrades: Keep your systems updated with the latest software and hardware enhancements.

- Continuous Monitoring: Use IoT-enabled devices for real-time performance tracking and diagnostics.

Industrial Control Systems Security: A Crucial Aspect

As industry automation systems become more sophisticated, securing these systems has never been more critical. Industrial control systems (ICS) are essential for monitoring and managing industrial processes. However, they are increasingly vulnerable to cyber threats, making security a top priority.

Threats to industry automation and Control Systems

Cyber threats targeting industry automation and control systems (IACS) are on the rise. These threats include:

- Malware attacks: Malicious software can disrupt operations and cause costly downtime.

- Phishing schemes: Cybercriminals use deceptive tactics to gain access to sensitive data.

- Insider threats: Employees or contractors may unintentionally or intentionally compromise system security.

- Ransomware attacks: Hackers encrypt critical data, demanding payment for its release.

The consequences of these threats can be devastating, ranging from financial losses to damage to a company’s reputation.

Best Practices for Industrial Control Systems Security

To mitigate these threats, companies should adopt robust security measures, such as:

- Regular vulnerability assessments: Identify and address potential weaknesses in the system.

- Implementing firewalls and antivirus software: Protect systems from unauthorized access.

- Employee training programs: Educate staff on recognizing and preventing cyber threats.

- Multi-layered security protocols: Use encryption and multi-factor authentication to safeguard sensitive data.

Implementing Robust Security Solutions for Industrial Automation

Investing in advanced security technologies is essential for protecting industrial automation systems. Solutions such as real-time monitoring, anomaly detection, and automated threat response can significantly reduce the risk of cyberattacks. Partnering with cybersecurity experts ensures that your systems remain secure while minimizing downtime.

Why Work with a Trusted Industrial Automation Company?

Choosing the right industry automation partner is crucial for the successful implementation and operation of automated systems. Here’s why partnering with a trusted company can make all the difference.

Benefits of Partnering with Experts in Industrial Automation

Working with experts ensures:

- Tailored solutions: Customization to meet specific operational needs.

- Enhanced efficiency: Streamlined processes that save time and resources.

- Access to cutting-edge technology: Integration of the latest advancements in automation.

- Improved safety: Implementation of safety protocols to protect workers and assets.

How to Identify the Right Industrial Automation Partner

When selecting an industrial automation company, consider the following:

- Experience and expertise: Look for a proven track record in your industry.

- Comprehensive services: Ensure they offer end-to-end solutions, from design to maintenance.

- Customer reviews: Check testimonials and case studies for insights into their performance.

- Technical support: Reliable after-sales service is essential for long-term success.

Future of Industrial Automation

The industry automation landscape is constantly evolving, driven by technological advancements and changing market demands. Let’s delve into the trends and innovations shaping the future.

Emerging Trends in Industrial Automation and Control Systems

Some of the key trends include:

- IoT Integration: Connecting devices for seamless data exchange and real-time monitoring.

- Edge Computing: Processing data locally for faster decision-making.

- Sustainability initiatives: Incorporating eco-friendly practices in automation solutions.

How Artificial Intelligence Enhances Industrial Automation

Artificial Intelligence (AI) is transforming industry automation by:

- Predictive maintenance: Using AI algorithms to predict equipment failures before they occur.

- Process optimization: Enhancing efficiency through intelligent process control.

- Quality assurance: AI-powered systems identify defects with unparalleled precision.

FAQs

Why is industrial automation important for modern businesses?

Industrial automation enhances productivity, reduces costs, and improves safety, making it essential for staying competitive in today’s market.

What are the best solutions for industry automation today?

The best solutions include IoT-enabled systems, AI-driven analytics, and robust cybersecurity measures tailored to your business needs.

What are the latest trends in industrial automation and control systems?

Emerging trends include edge computing, IoT integration, and AI-enhanced operations.

How does industrial automation improve manufacturing efficiency?

Automation streamlines processes, reduces human error, and ensures consistent quality, leading to increased efficiency and output.

What role does AI play in industrial automation solutions?

AI powers predictive maintenance, process optimization, and quality assurance, enabling smarter and more efficient operations.

Conclusion

Industrial automation is a game-changer for businesses looking to enhance efficiency, safety, and innovation. By implementing robust security measures, partnering with trusted experts, and staying ahead of emerging trends, companies can unlock the full potential of industry automation. As AI and other technologies continue to evolve, the future of industrial automation promises even greater advancements, bringing transformative solutions to industries worldwide.

It?¦s actually a cool and helpful piece of info. I?¦m happy that you shared this helpful info with us. Please keep us informed like this. Thank you for sharing.

Thank you for your kind words! We’re glad you found the information helpful. We’ll certainly continue sharing useful and informative content—your support is much appreciated.

Thanks a lot for giving everyone an extremely special opportunity to discover important secrets from this web site. It can be very kind and as well , jam-packed with fun for me personally and my office acquaintances to visit your site at the very least 3 times every week to see the latest issues you have got. And lastly, I am usually amazed considering the tremendous methods you serve. Selected 1 ideas in this posting are undeniably the most impressive we have had.

Thank you so much for your thoughtful feedback! We’re thrilled to hear that you and your colleagues find the site both enjoyable and valuable. Your kind words about our content and methods mean a great deal, and we’re delighted that some ideas resonated so strongly with you. We truly appreciate your support!

Excellent web site. Lots of helpful info here. I?¦m sending it to a few friends ans additionally sharing in delicious. And naturally, thanks on your effort!

Thank you so much! I’m glad you found the content helpful and appreciate you sharing it with your friends.

I’d incessantly want to be update on new articles on this site, saved to favorites! .

Thank you! I’m glad you’re enjoying the content—stay tuned for more updates coming soon!

But a smiling visitant here to share the love (:, btw outstanding design and style. “Competition is a painful thing, but it produces great results.” by Jerry Flint.

Thank you so much! I’m glad you enjoyed the design and appreciate you sharing the love. That’s a great quote—thanks for including it!

Hello! Quick question that’s completely off topic. Do you know how to make your site mobile friendly? My weblog looks weird when browsing from my iphone4. I’m trying to find a theme or plugin that might be able to correct this problem. If you have any suggestions, please share. Cheers!

Hi! No worries, happy to help. For a mobile-friendly site, using a responsive theme is key—most modern WordPress themes are responsive out of the box. You can also use plugins like WPtouch to improve mobile display. Make sure to test on different devices to see how it looks. Hope that helps!

Some genuinely howling work on behalf of the owner of this web site, absolutely outstanding content.

Thank you so much! I truly appreciate the kind words and support.